Automation and robotics are two completely different, however intently associated ideas. Each are a part of the each day lifetime of many industries and assist to streamline, make worthwhile, and optimize inner processes.

Automation refers to a broad idea that includes utilizing know-how to carry out duties routinely, with out direct human intervention.

Robotics is an interdisciplinary scientific subject utilizing engineering, laptop science, and different disciplines to design, construct, and function robots, that are programmable machines that may full duties autonomously or semi-autonomously.

On this article, we spotlight the key variations between automation and robotics. Then, we go into extra element about every and conclude with future traits.

Key Variations and Commonalities

Automation refers back to the strategy of automating duties utilizing know-how, which can or might not embrace robots. Examples of automation know-how embrace the programming of laptop techniques, particular software program for the management of business processes, or the implementation of constructing management techniques.

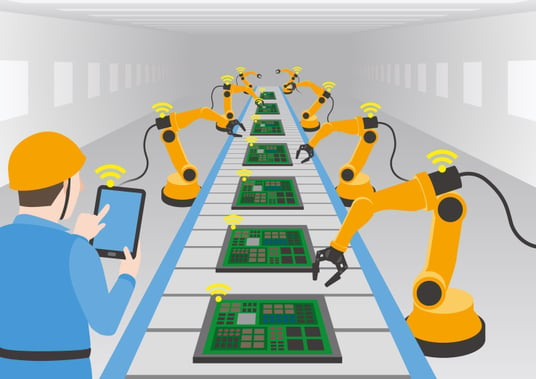

Robotics focuses on the design, development and programming of robots to carry out particular duties. Examples abound from robots particularly designed to assemble parts on a manufacturing line to these meant to hoover flooring or mow lawns.

Robotics and automation know-how can be utilized collectively or individually relying on the target and desires of a venture or firm. As we are going to see, each fields present related advantages to bodily processes, enterprise processes, and to the competitiveness of an organization.

What Is Automation?

Automation means utilizing laptop software program, machines, or different know-how to hold out a process which might in any other case be completed by a human employee. It thereby frees up that employee’s time to focus on extra advanced and strategic actions.

There are a lot of varieties of automation, starting from the totally mechanical to the totally digital, and from the quite simple to the extraordinarily advanced.

Forms of Automation

Let’s check out the 2 predominant varieties of automation: software program automation and industrial automation.

Software program automation is used to carry out duties usually completed by individuals on computer systems. There are quite a few branches, varieties, and traits of software program automation: take a look at automation, robotic course of automation (RPA), Clever Automation, and extra. Software program automation consists of robotic course of automation the place robots deal with repetitive digital duties, and clever course of automation which integrates with AI for smarter automation. Automating workplace duties can contribute to bettering enterprise processes.

Industrial automation includes bodily processes which are automated with bodily robots and particular management techniques. It might probably contain single machines doing particular duties or a totally automated manufacturing line. Industrial automation is an more and more essential side of optimizing manufacturing and manufacturing processes. There are several types of industrial automation:

-

Fastened Automation, often known as inflexible automation, includes the implementation of techniques designed to hold out particular duties in a repetitive method and in a single location. A typical instance of mounted automation is an meeting line within the automotive trade, the place robotic arms carry out meeting duties in sequence.

-

Programmable Automation permits for agility in manufacturing as software program is reprogrammed or reconfigured to adapt to completely different merchandise or processes. Not like with mounted automation, programmable automation permits a robotic to be reprogrammed to vary the sequence of operations or manufacturing parameters as essential.

-

Versatile Automation takes it one step additional by enabling speedy adaptation of manufacturing techniques to fulfill evolving market demand. An instance of versatile automation can be a manufacturing facility creating digital parts, the place manufacturing cells adapt to adjustments in product design or demand.

-

Clever Automation, additionally known as cognitive automation or trade 4.0, depends on superior applied sciences equivalent to synthetic intelligence, machine studying and information analytics to optimize industrial processes. Clever automation permits for autonomous decision-making and real-time adaption to adjustments within the manufacturing setting. An clever automation instance can be bots utilizing sensors and information evaluation to foretell and stop

Automation Advantages

Automation is all about utilizing know-how to make duties simpler and extra environment friendly. It includes utilizing machines or laptop software program to do jobs that people normally do. By delegating duties usually carried out by people, automation addresses a number of widespread points:

-

Labor scarcity: It’s more and more tough to search out, practice, and maintain employees who carry out repetitive duties. Having automation take over these jobs not solely helps decrease the variety of employees wanted, but additionally permits employees to concentrate on extra fascinating and strategic actions, which is more likely to encourage them stick with the corporate in the long term.

-

Security: Repetitive duties current well being and issues of safety as they expose employees to harm. Automation can forestall these security hazards.

-

Effectivity: Not like people, machines can run constantly with out fatiguing whereas remaining exact. This will increase output and reduces error.

-

Aggressive edge: Corporations that implement automated techniques acquire a aggressive benefit by bettering effectivity, reducing prices, and providing larger high quality merchandise.

At its core, automation is about enhancing effectivity and precision within the digital in addition to bodily world.

What’s Robotics?

Robotics is a department inside the broader subject of automation, focusing particularly on bodily robots. It incorporates a number of disciplines to design, construct, program and use robotic machines. These robots can remodel the way in which we work.

Typically, the objective of robotics is to automate duties or processes. Nevertheless, robotics is a subset of automation that focuses particularly on the event and manufacturing of robots.

Forms of Robots

Let’s check out three varieties of robots: industrial robots, service robots, and humanoid robots.

-

Industrial robots are utilized in factories and warehouses to automate duties like welding, meeting, and materials dealing with. They’re designed for precision, velocity, and repeatability, and are sometimes stationary. Industrial robots are versatile and could be reprogrammed to carry out numerous duties. They’re most frequently utilized in printing, packaging, welding, machine tending, materials dealing with, and metalwork.

-

Service robots are utilized in properties, hospitals, inns, places of work, airports, museums, and buying malls to carry out duties like cleansing, greeting guests, or making deliveries. They’re made to work together with people and are normally extra reasonably priced and fewer advanced than industrial robots. Examples embrace a robotic vacuum cleaner or garden mower or an interactive robotic greeter at a health care provider’s workplace.

-

Humanoid robots appear like human beings. They’re programmed to work together with the setting in ways in which a human would possibly and may have facial options to imitate emotion. Sophia is an instance of a humanoid robotic. Sophia is embedded with neural networks and synthetic intelligence to acknowledge human faces and perceive their gestures and feelings and reply appropriately.

Robotics Advantages

Robotics have myriad advantages together with, however not restricted to:

-

Improved accuracy and consistency – Robotic techniques are exact, making their output each correct and constant. They nearly remove human error.

-

Improved product high quality – Robots will not be affected by fatigue or distraction as a result of repetitive duties the way in which that people are. This improves high quality assurance.

-

Extra effectivity and output – Not like human employees, robots don’t must take breaks or have set work shifts, so manufacturing can function 24/7. Higher high quality assurance means fewer wasted merchandise and larger yield.

-

Job creation and worker retention – Opposite to common perception, robots will not be eliminating jobs, however creating new ones! Now that guide and repetitive duties could be delegated to machines, people can rise to roles the place the abilities could be higher used and developed. For instance extra software program builders, and programmers are wanted to service and preserve robots, and new professionals shall be required to maintain the automated manufacturing line operating easily. This profession development usually results in elevated worker satisfaction and retention.

-

Elevated office security – Engaged on a manufacturing line could be significantly harmful for human employees. Permitting robots to tackle the strenuous, repetitive duties takes people out of hurt’s approach.

Future Developments in Automation and Robotics

So what does the long run maintain for automation and robotics? As each fields proceed to revolutionize industries by bringing extra precision, effectivity, and security to numerous processes, automation and robotics will remodel present industries and in addition act as a catalyst for brand new sectors to emerge.

Listed below are our predictions for upcoming traits in automation and robotics:

-

Integration of AI – Steady developments in AI and machine studying are making automation techniques extra clever and adaptive. Which means that future robots will transcend simply performing repetitive duties; they may even be able to making advanced selections, analyzing real-time information, and studying from their environment, boosting productiveness and minimizing human error.

-

Collaborative robots (Cobots) – Collaborative robots, often known as cobots, are designed to work alongside human workers with out security limitations. They’re designed with security and adaptability in thoughts, permitting them to carry out numerous easy or advanced duties, whereas remaining simple sufficient for non-experts to program and deal with. We are going to see a rise of their implementation throughout industries.

-

Growth in non-industrial sectors – The flexibility of robotics and automation permits for his or her utility throughout a spread sectors, together with healthcare, agriculture, providers, and extra. Widespread adoption will result in uniform development and innovation, contributing to financial stability and job creation in new areas exterior of repetitive duties.

Do you may have any queries concerning the variations between varieties of automation? Ask us within the feedback under or be a part of the dialogue on LinkedIn, Twitter, Fb or the DoF skilled robotics neighborhood.