Final winter we had been invited to take a uncommon look contained in the Ortlieb manufacturing unit, the place the corporate synonymous with ‘waterproof’ manufactures their traditional touring, commuter, and bikepacking baggage. Nestled within the rolling rural countryside of northern Bavaria, Ortlieb makes its signature waterproof biking baggage in Germany. For over 40 years they’ve constructed a repute for high quality, sturdiness, and reliability. And whereas they’ve expanded their choices far past their authentic waterproof touring baggage and people authentic designs, Ortlieb even continues to refine and evolve these traditional baggage which are nonetheless a few of their greatest sellers…

Inside Ortlieb, behind the scenes the place waterproof is made

Throughout a much less busy, however appropriately wet a part of the 12 months, we had an opportunity to enterprise throughout Germany to the headquarters of Ortlieb in Heilsbronn within the Franconia area. Fairly centrally situated in Germany – and technically on the geographical middle of the EU – it’s a straightforward locale to miss. But it surely’s a pleasant, quiet a part of the German countryside. And sufficiently moist for his or her fashion of substances, a minimum of based mostly on my winter go to.

He began the corporate again in 1982 in Nuremberg, however Hartmut Ortlieb introduced it half an hour down the street to this new location in 1997 to arrange a extra environment friendly, extra sustainable approach of producing their iconic waterproof gear. That’s the place greater than 300 worldwide staff design and make your baggage, and create all of their rising vary of substances – past touring & bikepacking baggage to incorporate a number of racks, thru-axles & extra…

The entire waterproof baggage are created in-house in Heilsbronn. Their specialised waterproof zippers are made by a accomplice firm Tizip, actually created on the identical road simply to make zips to Ortlieb’s excessive waterproof requirements the 12 months after they moved to Heilsbronn. All of the injection molded plastic components in your Ortlieb gear are additionally made on the identical tiny dead-end road. Ortlieb constructed up the business on the sting of this small, to the purpose that their companions actually can pull a forklift out of 1 manufacturing unit and drop it off subsequent door, for essentially the most easy-to-mange provide chain logistics you’ll discover anyplace.

The place Ortlieb waterproof began, and the place they’ve gone

Ortlieb acquired its legendary begin in 1982 when founder Harmut Ortlieb wasn’t happy with the shortage of safety from the weather with touring baggage of the time. On a cycle tour of the UK, he realized that the tarps overlaying truckers’ hauls would make higher baggage than the axed cotton or uncoated nylons of the day. So he returned dwelling and began experimenting with tarpaulin material and his mom’s stitching machine.

He began with taped seams, that had been almost “leakproof”. However that wasn’t adequate. Inside about 2 years, Harmut settled on high-frequency welding tech to bodily bond two items of coated material collectively – creating actually waterproof gear. That’s nonetheless the core expertise that units Ortlieb aside in the present day – though it has develop into way more subtle and refined.

It began with Ortlieb’s first tarp-based and seam-taped Bike-Packer pannier baggage. 40 years later, the overall pannier bag profile is analogous, even all the way down to the 2-strap closure, and the enduring purple. However the supplies of the trendy Bike-Packer Plus are way more refined. And the high-frequency welded seams are unmatched for his or her constant waterproofness and sturdiness.

Behind-the-scenes in waterproof biking bag manufacturing

To make all their high-performance baggage, Ortlieb has to start out with high-quality supplies. Their materials are all offered by long-term trusted suppliers. And Ortlieb retains loads of rolls in inventory, in all of their favourite colours, to take care of dependable workflow.

It’s not solely the traditional coated nylon & polyester materials, extra advanced development contains varied foams, foils, and different plastics that give Ortlieb’s merchandise a variety of functions. And all of them have to be sorted, prepped, and saved to be prepared for Ortlieb’s versatile manufacturing.

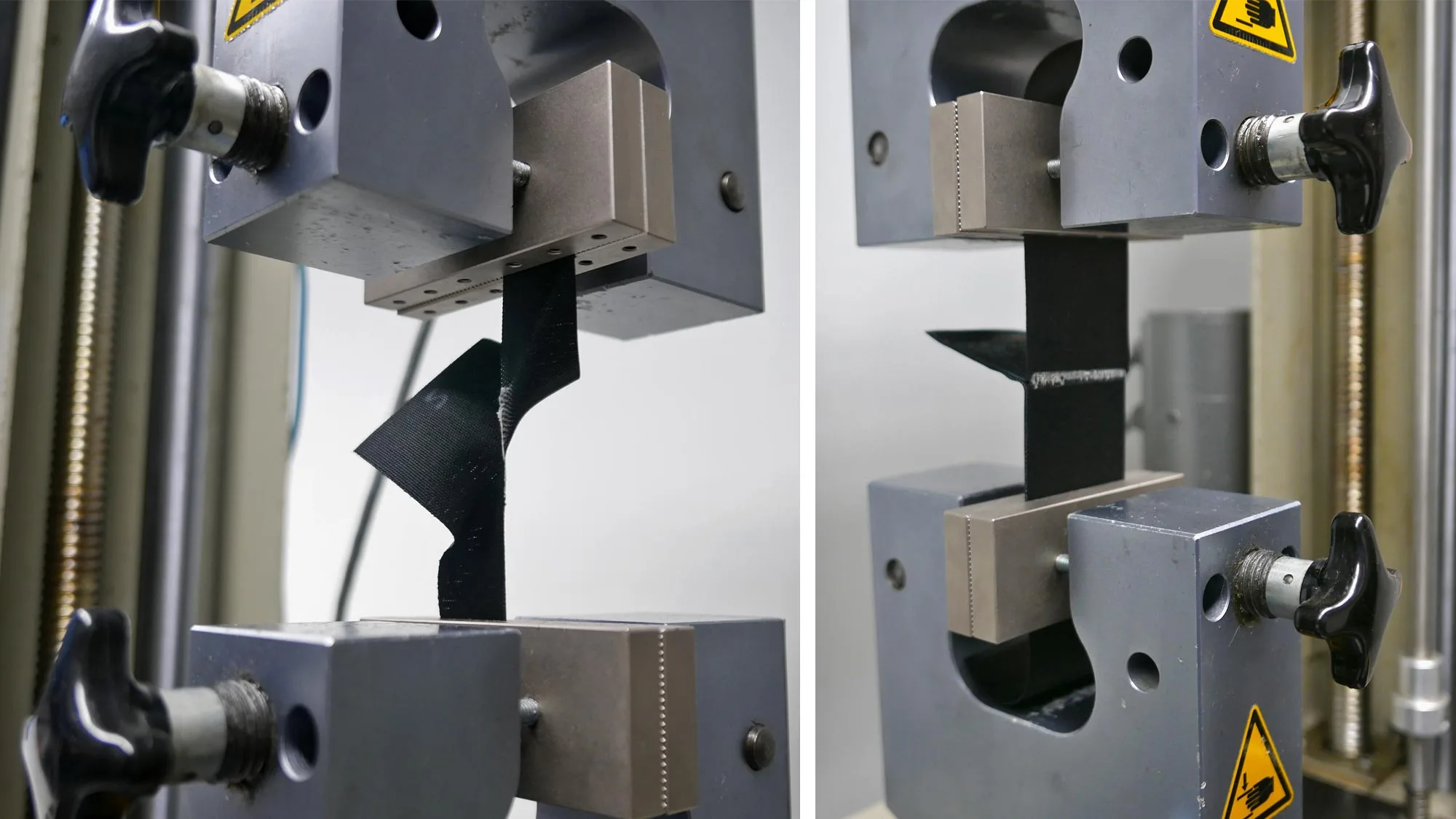

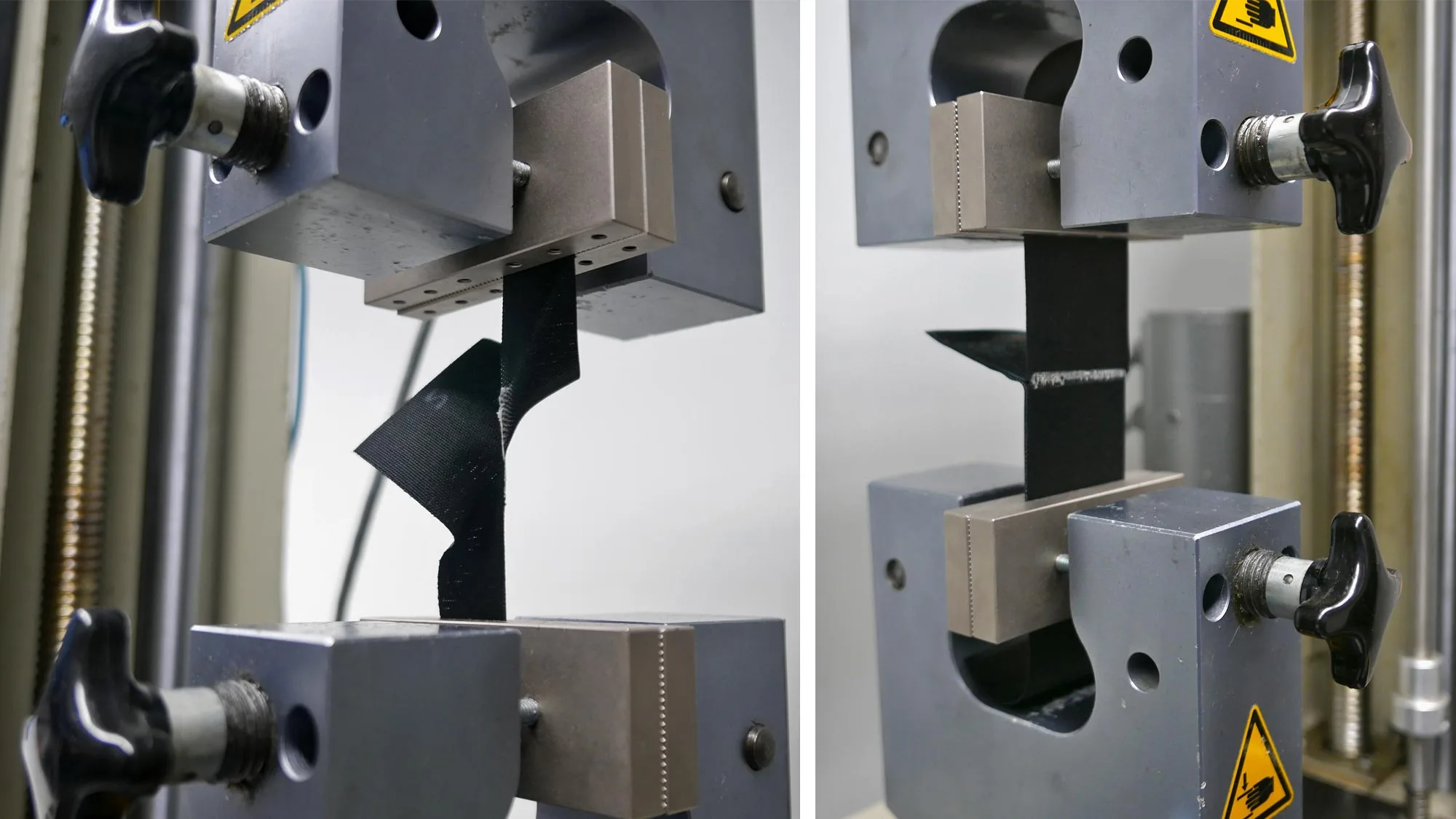

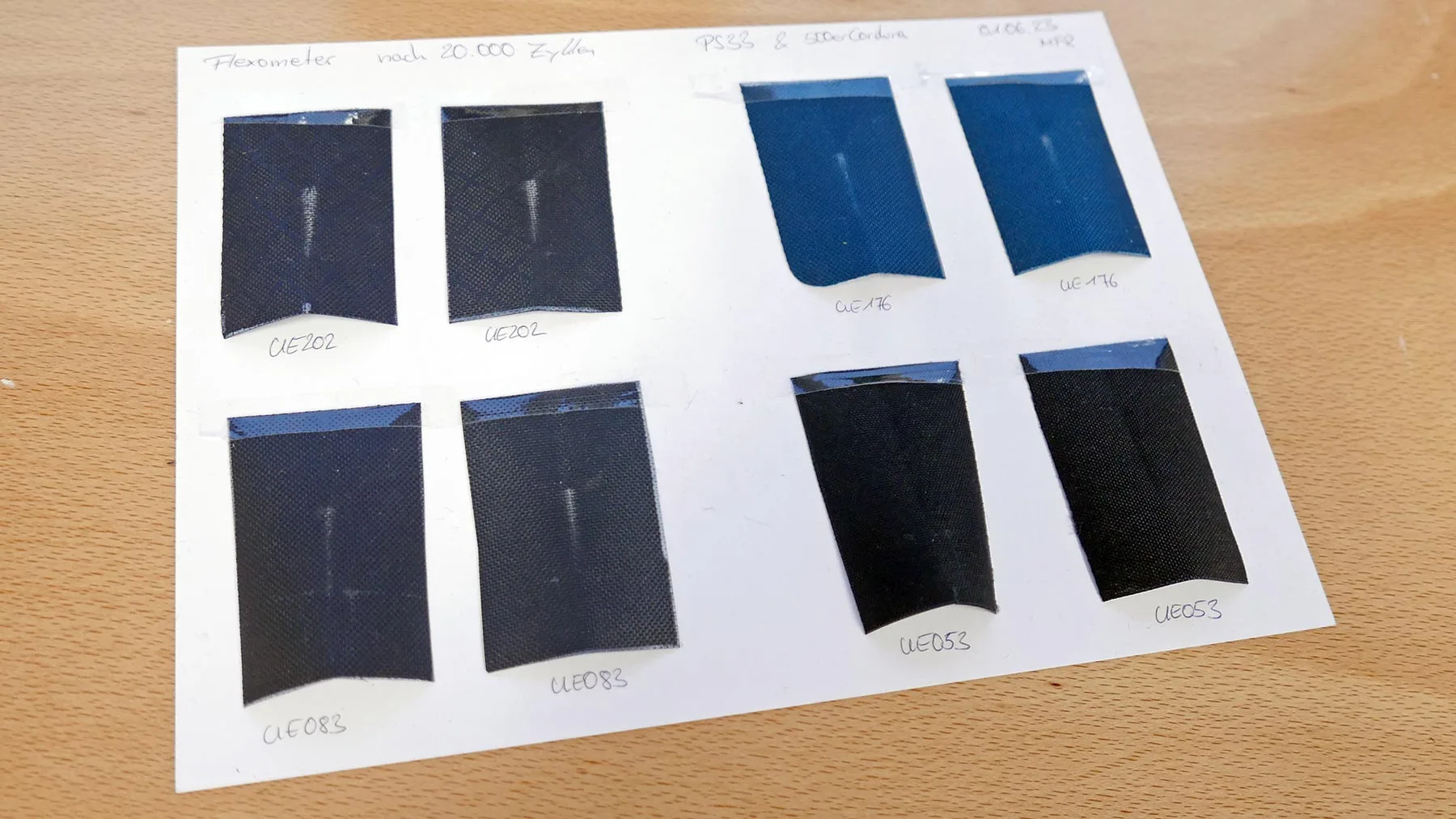

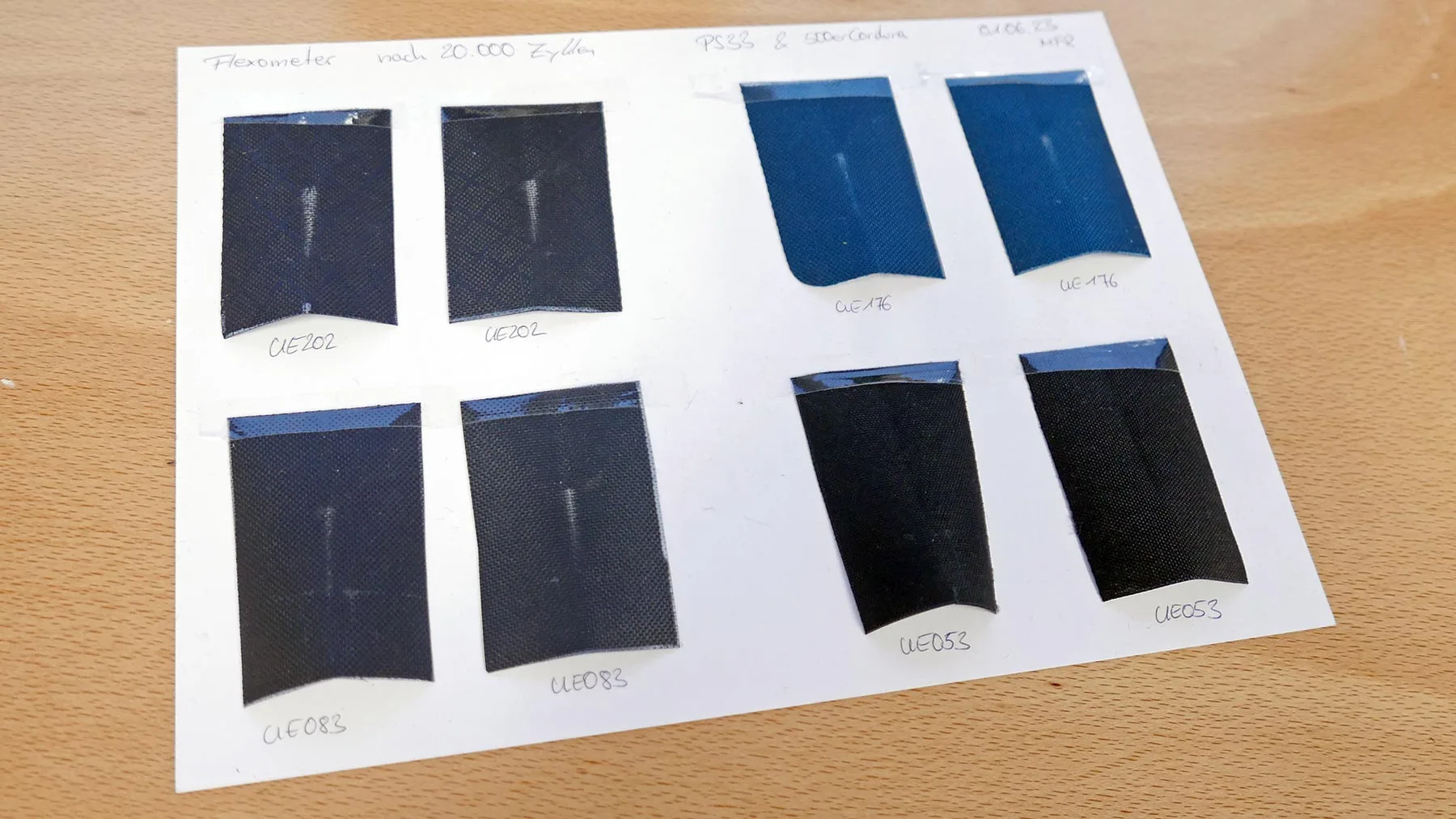

In-house materials testing

However trusted suppliers or not, Ortlieb doesn’t depart something to probability. It’s their waterproof repute on the road, in spite of everything.

So each batch of material coming within the door will get examined in-house. Tear resistance, final tensile power, skill to be welded collectively, abrasion resistance, waterproofness. Very like of their manufacturing corridor, Ortlieb makes lots of their very own testing instruments to find out the efficiency of their uncooked supplies.

And if the material doesn’t go any of Ortlieb’s in-house exams, it doesn’t make it into any manufacturing baggage.

Materials reducing & prep

Over 40 years, many steps of the manufacturing of Ortlieb’s iconic baggage have developed and develop into extra environment friendly. That’s an enormous motive that they will proceed to fabricate in Germany. Whereas their merchandise are on no account the most cost effective in the marketplace, clients proceed to respect the added worth of high-quality, sturdy gear that Ortlieb stands behind.

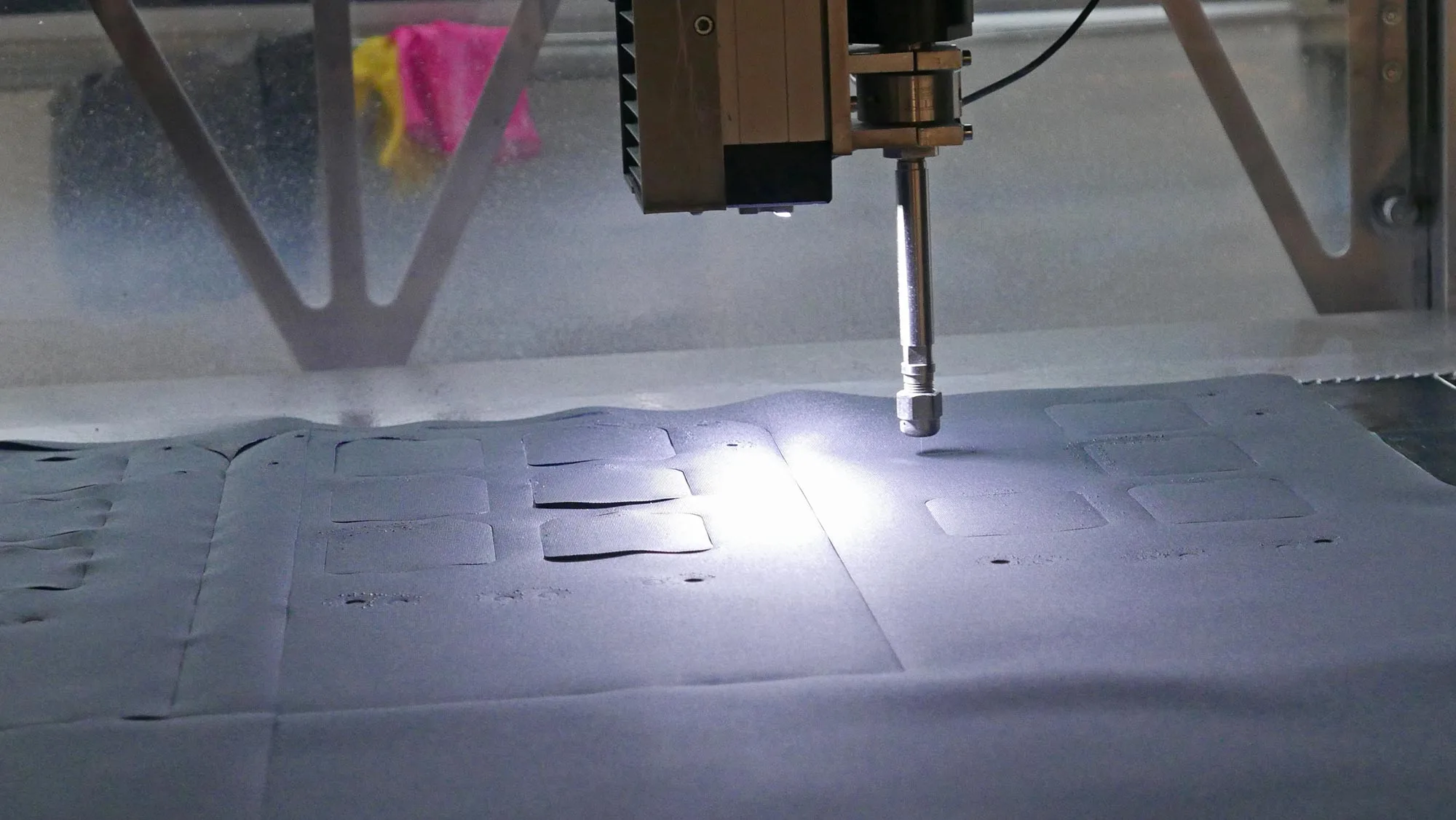

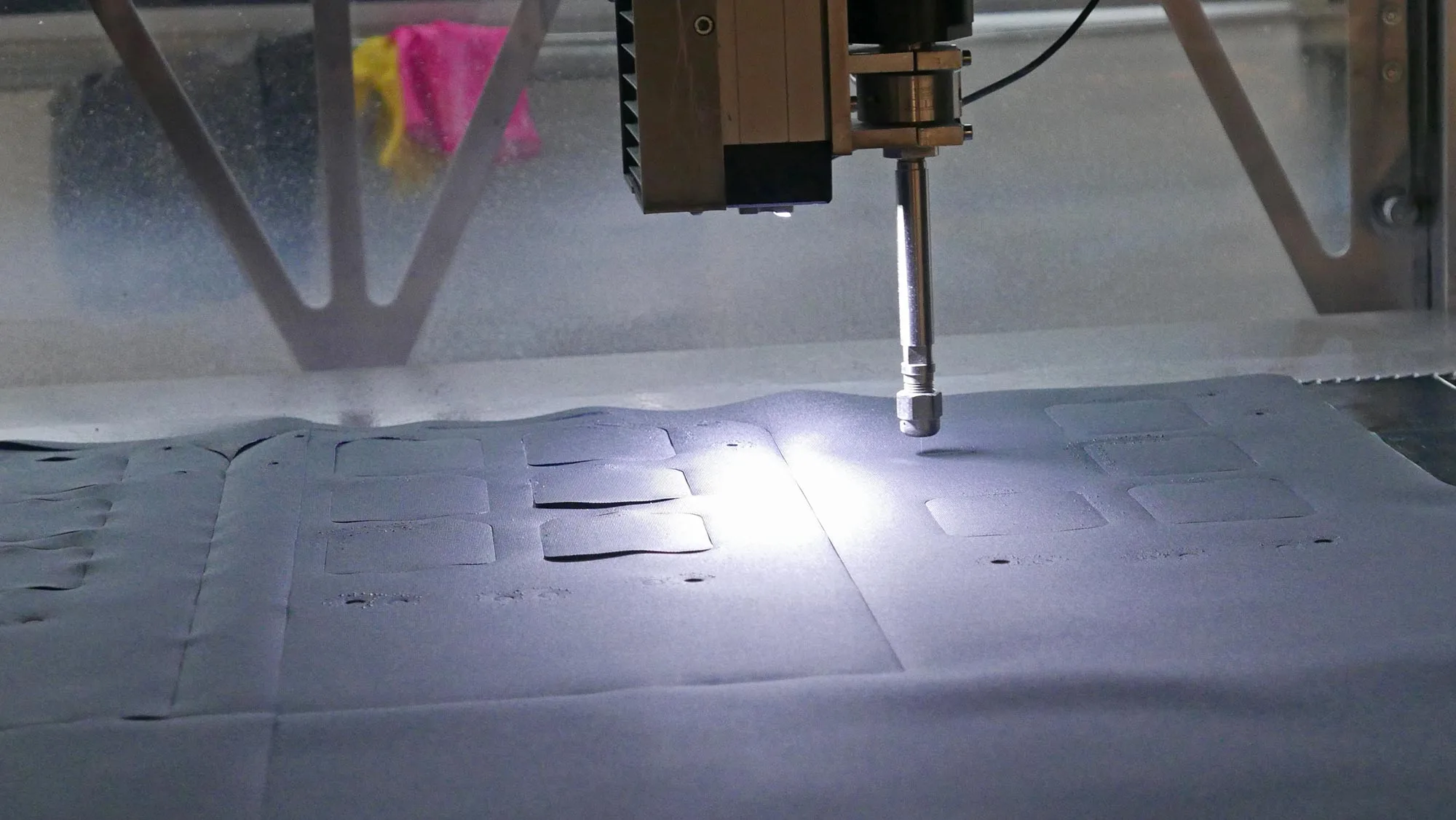

Water jet reducing lets Ortlieb precisely reduce many layers of fabric at a time, dashing up the prep course of for his or her greater quantity baggage.

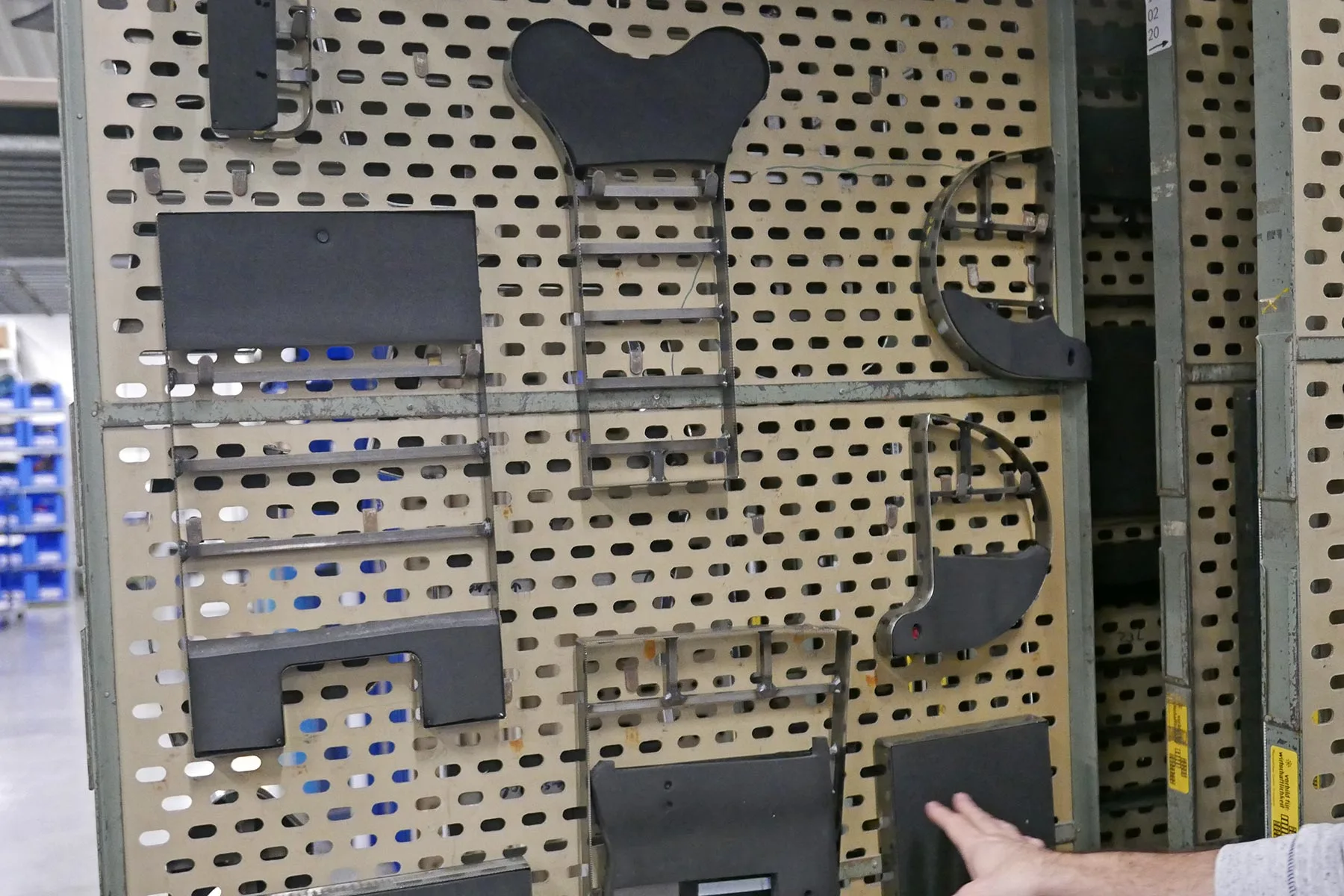

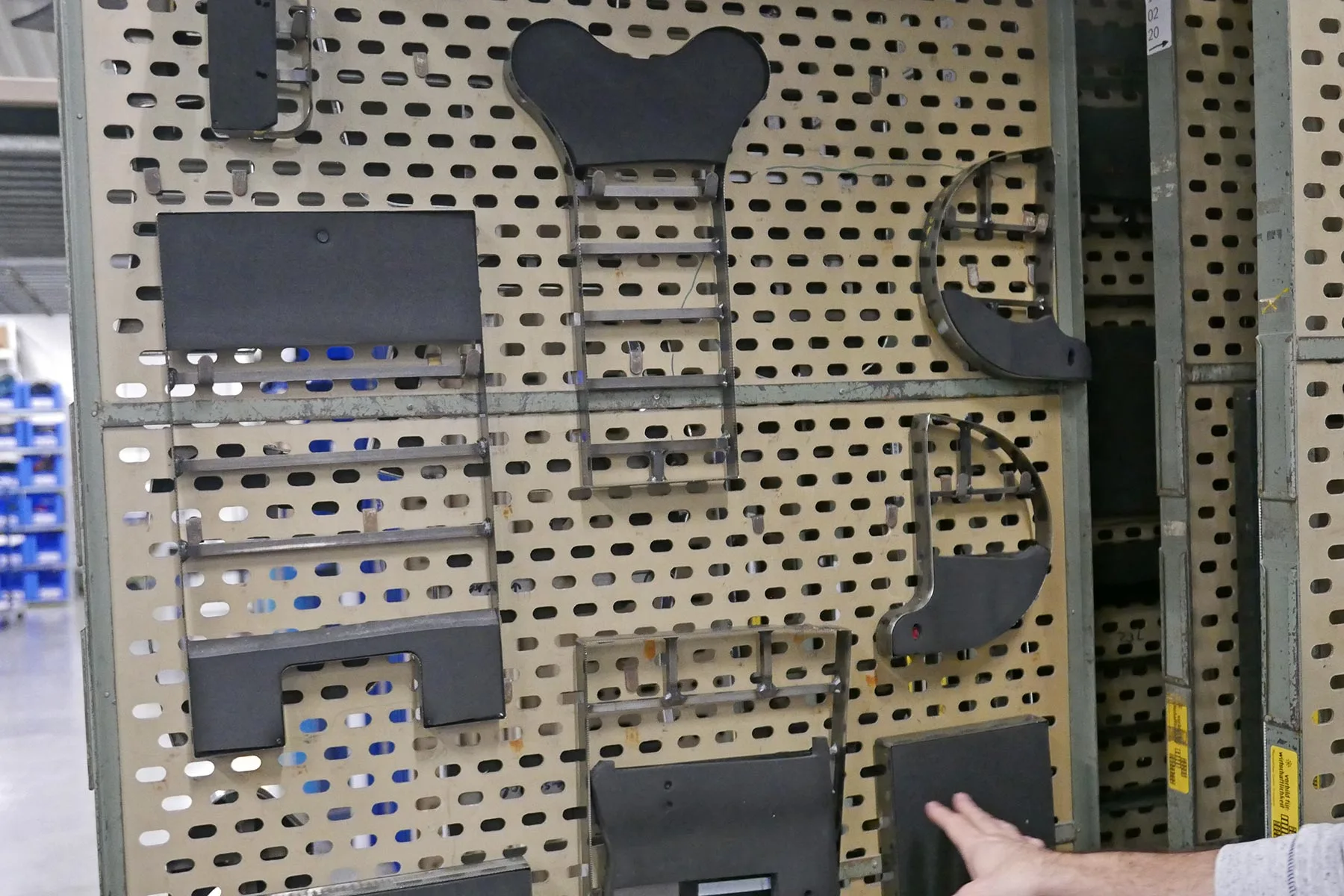

However their traditional stamping dies nonetheless see common use too. For decrease quantity or thicker foam supplies, usually instances the traditional die-cutting course of continues to be the most effective resolution. And Ortlieb has a veritable library of dies to stamp out all shapes & sizes of their broad catalog of cycling-specific baggage and extra normal utility packs.

One of many video games that the Ortlieb workforce likes to play with the uninitiated is “Guess what bag that is?”

Many are fairly straightforward to determine if you’re accustomed to their core biking baggage. However can anybody guess which bag these yellow items belong to? Tell us within the feedback!

What’s within the Bike Bag field?

Now, let’s dive into the delivery of a single bag (or a minimum of a single household of luggage).

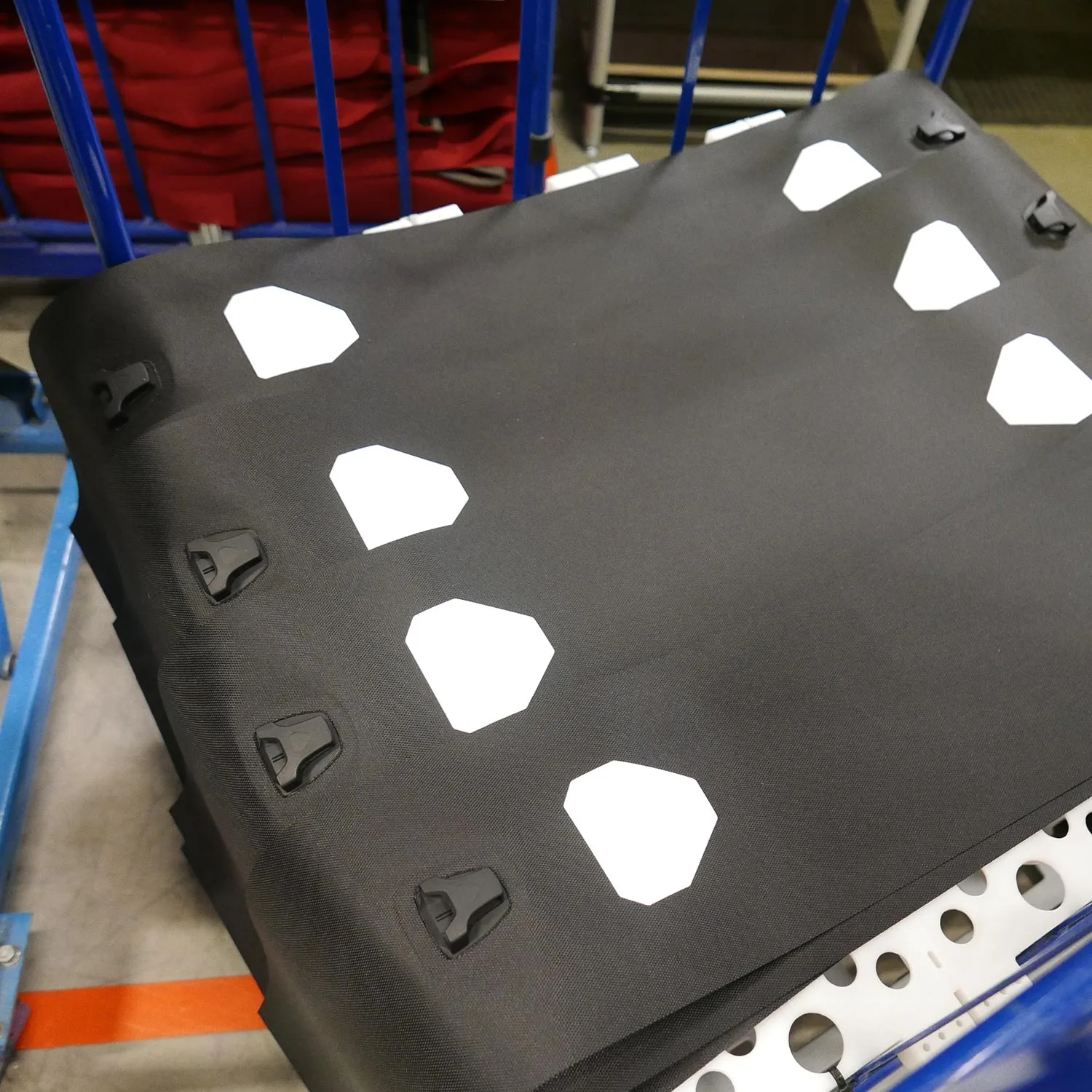

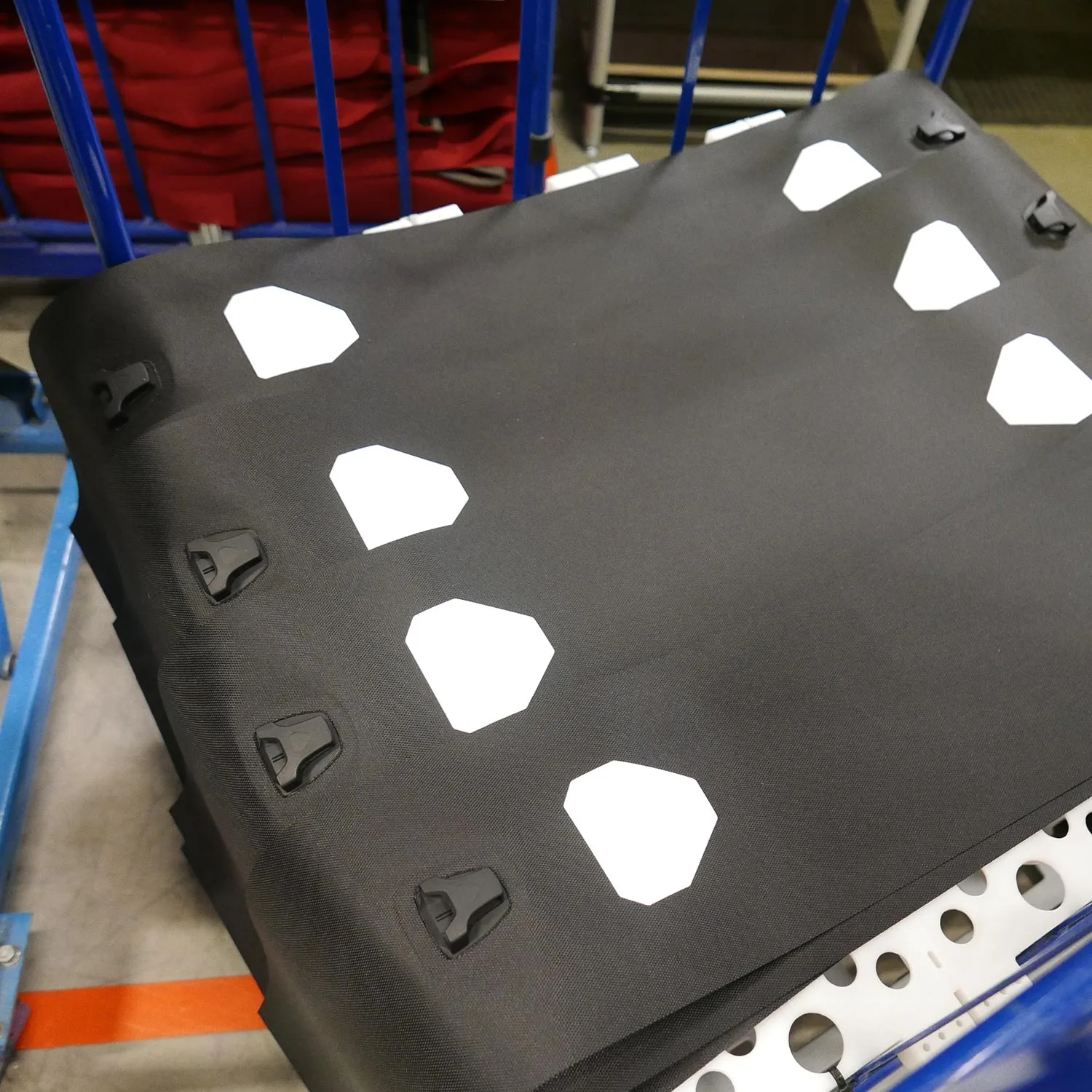

The Ortlieb guessing recreation continues. What ‘Bike Bag’ in within the field?

At varied levels within the manufacturing course of, Ortlieb water jet cuts (or die cuts) the person panels that make up a bag. Then, they print or heat-transfer the graphics onto the person panels – hi-viz reflective right here. Then, they could weld on {hardware} like these aspect buckles.

Earlier than…

The subsequent thriller step.

Herein lies the secrets and techniques…

Ortlieb was cautious to not actually present us how they use their distinctive & patented high-frequency welding tech to bond the person panels of their baggage collectively. It’s actually the key sauce that units them other than the competitors.

I did get to see some interesting-looking, custom-made welding machines that had been dormant throughout my time within the manufacturing unit. Every was created for a selected product, such as you may see with a carbon wheel or body mildew. And the overall concept appears to be that these machines had been developed to pay attention the high-frequency vitality solely on the particular bag’s seams, so these are melted collectively, however nothing else is affected.

Fascinating to notice with out know extra about how the method works, there have been warning indicators in every single place so that somebody with a pacemaker didn’t by chance stray into the trail of an Ortlieb waterproof bag welding machine in-process.

Take into account your self warned.

Again to traditional bag meeting…

As soon as Ortlieb mysteriously makes use of a magic microwave to bond your bag’s panels collectively in a water-resistant development, there’s nonetheless lots extra handbook work to be achieved.

Expert staff sew on ending tape, and the particular skinny piece of stiffening plastic that makes their roll-top closure work so nicely.

Bear in mind, Ortlieb really is the inventor of the waterproof roll-top closure. And you could fold it a full 3 instances for Ortlieb to ensure that it’s actually waterproof. A minimum of shielded from 1m submersion in water for a full half-hour. In actuality, most Ortlieb waterproof baggage ship considerably extra safety than that.

After welding and that final stitching step, these baggage lastly resemble one thing that we are able to simply determine.

At that time, groups of two work collectively to complete the Ortlieb baggage. They bolt on specialist {hardware} – just like the QL2.1 quick-release rack attachment system right here. And so they add any remaining straps, hooks, and buckles earlier than the entire baggage get boxed as much as ship to the warehouse for distribution.

Did you guess which baggage we had been seeing be made?

The unfinished aspect panels had been from this (probably purple) Ortlieb Again-Curler Core pannier bag. And the marginally nearer to being completed petrol blue baggage had been these traditional and barely extra advanced Again-Curler panniers.

Manufacturing facility seconds discover a 2nd life

One casualty of Ortlieb’s insistence on absolute waterproofness and exacting high quality management is that not each bag they begin engaged on finally ends up passing all their inside checks.

However turning lemons into lemonade, Ortlieb places their manufacturing unit seconds apart, after which provides them a second life – right here as high-quality, however not waterproof reusable procuring baggage. Their sellers can place orders for as many as they need, however no selection on colour, since they’re solely made with no matter doesn’t go inside quality control.

Repair It, Don’t Exchange It!

That was the tagline of an Ortlieb Restore Week marketing campaign final 12 months as a response to business Black Friday offers. But it surely’s greater than only a slogan. Ortlieb affords a 5-year guarantee on each product they make. However in addition they encourage patrons to make use of their gear long gone that.

A giant a part of preserving their current gear in service is an inexpensive restore program, and availability of spare components. Ortlieb trains an enormous portion of their sellers & distributors in additional primary and the commonest repairs, and even units up a lot of them for extra advanced repairs.

And if you happen to can’t get somebody native to repair your gear, Ortlieb sends it again to Heilsbronn the place it was made. Off in a single nook is the manufacturing unit, we discovered a well-equipped restore technician. And he picked out what he was engaged on that day, all the pieces from changing broken {hardware} to displaying us how he makes use of a particular warmth gun & curler to weld patches over broken packs to make them totally waterproof once more.

Then stack it up, and ship it out

Ortlieb makes all of their waterproof touring, commuting, bikepacking, and off-bike baggage in-house in Germany.

However even these newer gadgets like tubular aluminum racks and modular thru-axles that aren’t manufactured in Heilsbronn, all of them nonetheless find yourself right here within the Ortlieb warehouse to get shipped out to world distributors and your native supplier bike retailers.

A living proof Assessment: Why Ortlieb biking baggage are waterproof!

One last item…

Whereas visiting Ortlieb in Heilsbronn, it appeared like it will be a disgrace to not load up some bikes to get moist & muddy. You understand, to see what waterproof biking packs had been all about.

For a fast 2-day bikepacking overnighter, I loaded up the 3T Extrema Italia check bike with my set of restricted version purple, petrol & orange Ortlieb bikepacking baggage filled with loads of gear to remain heat and dry this previous winter. And naturally, heavy rain was forecast, and the gravel route was extra dust farm tracks and singletrack, so I broke out the Maxxis Extreme 29er XC mud tires for as a lot grip as I may muster up.

My Ass Savers Win Wing was no match for the sloppy moist German mud, though I believe it did really hold my legs a bit cleaner and drier.

So did all the pieces keep dry?

After all it stayed dry.

Nicely, a minimum of all the pieces inside my Ortlieb waterproof bikepacking baggage.

The primary trick with using gravel bikes in rain and dirt is discovering a spot out of the rain when it’s time to load and unload your baggage. The second is attempting to maintain the baggage clear of mud earlier than it’s important to open, or shut them once more.

The Seat Pack saddlebag is the toughest to take care of preserving clear, so I attempt to restrict how usually I have to get into that one – often saving that for the top of the journey at camp. The Handlebar Pack doesn’t get as mucked up at its openings, however the finish openings are typically tough to open, then shut once more tightly whereas nonetheless on the bike. So that they’re not solely for camp, too.

The roll-closure Body-Pack High Tube RC is my go-to for further layers, instruments, and greater snacks that come out mid-ride. It’s straightforward to get into with a gaping huge opening, and doesn’t get soiled mid-ride.

Then lastly, this magnet snap-closure toptube Gasoline Pack is great for smaller snacks, and to maintain your telephone and powerbank dry in a deluge. One-handed easy accessibility, and it nonetheless retains rain out. Simply don’t dunk it in a lake, because it’s not immersion-proof like the remainder of the Ortlieb baggage are.

Ortlieb waterproof will hold dry what you like

Sure, I’m totally onboard with the “Preserve Dry What You Love” mantra. Plus, I really like that Ortlieb builds these baggage to final. And Ortlieb backs them with restore service to maintain them in use for so long as you need to hold the using your bike on new adventures.

Now fact be instructed, I’ve already spent many tons of of kilometers with my gear shielded from the weather inside Ortlieb waterproof bikepacking baggage. And I even rode to the prepare station within the rain this morning with my weekend’s price of substances safely tucked away inside Vario convertible pannier/backpack connected to a Fast-Rack Mild.

So, I already knew these colourful bikepacking baggage would hold my goodies dry.

However you possibly can’t blame me for taking a possibility to go play within the mud & rain with Ortlieb’s head of communications.

It was nice to see inside Ortlieb how they manufacture these baggage in Germany. However the journey was even higher by taking my well-used baggage again to their birthplace. After which, inundating the baggage with actually the identical rain and dirt that Ortlieb created them to guard your gear from within the first place, for the previous 42 years.