OK, so, technically this new Lauf Cycles rear hub design may have “1000’s” of factors of engagement per rotation, however which may as properly be infinite. Also referred to as instantaneous.

Both approach, the impact is that the hub will interact so rapidly that it’s going to really feel quick, and it does this with a really intelligent staggered, doubtlessly “elastic” pawl design that additionally softens engagement and will be positioned all through the hub’s total shell.

Oh, and it does all of this with out magnets or springs.

How Lauf’s hub design works

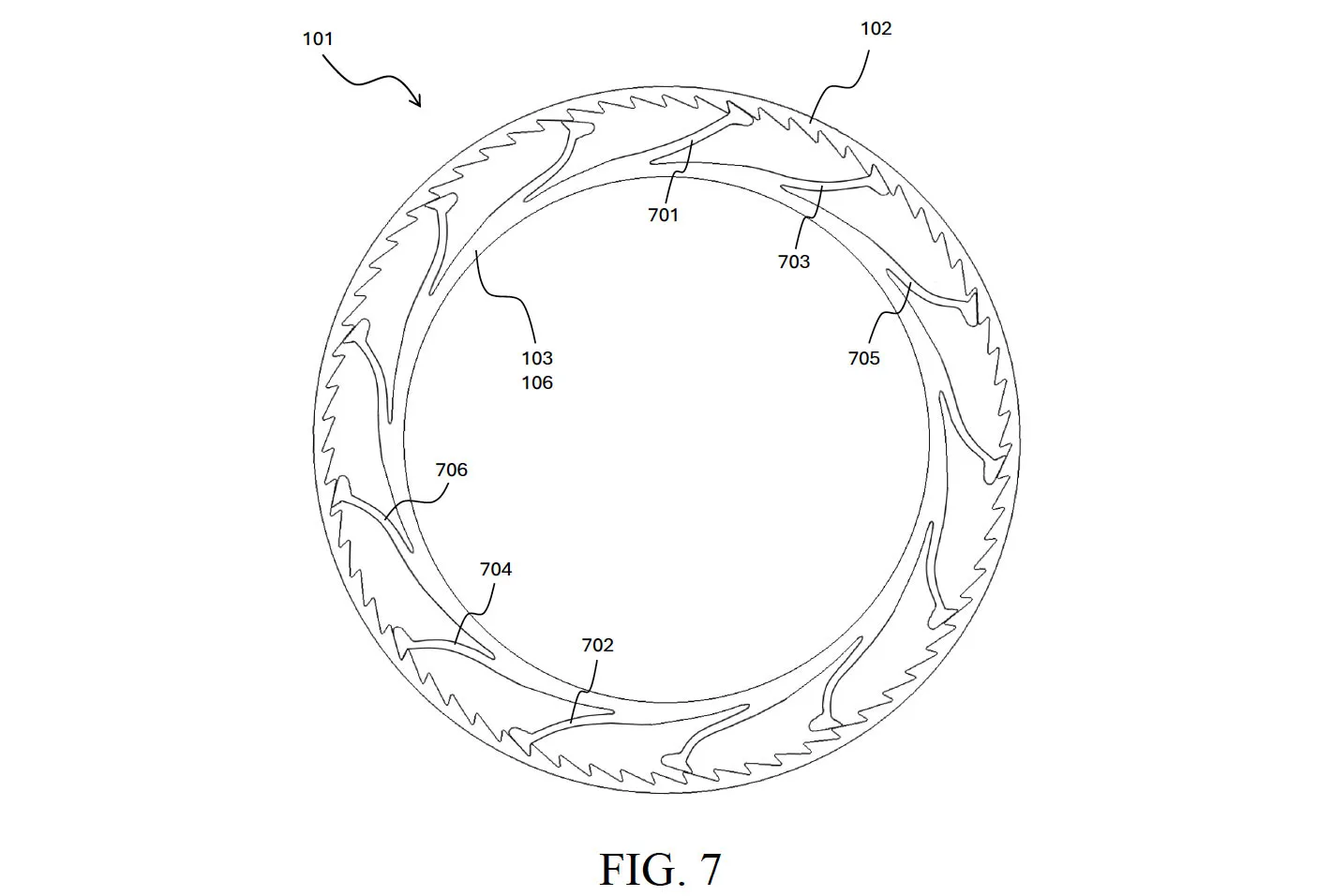

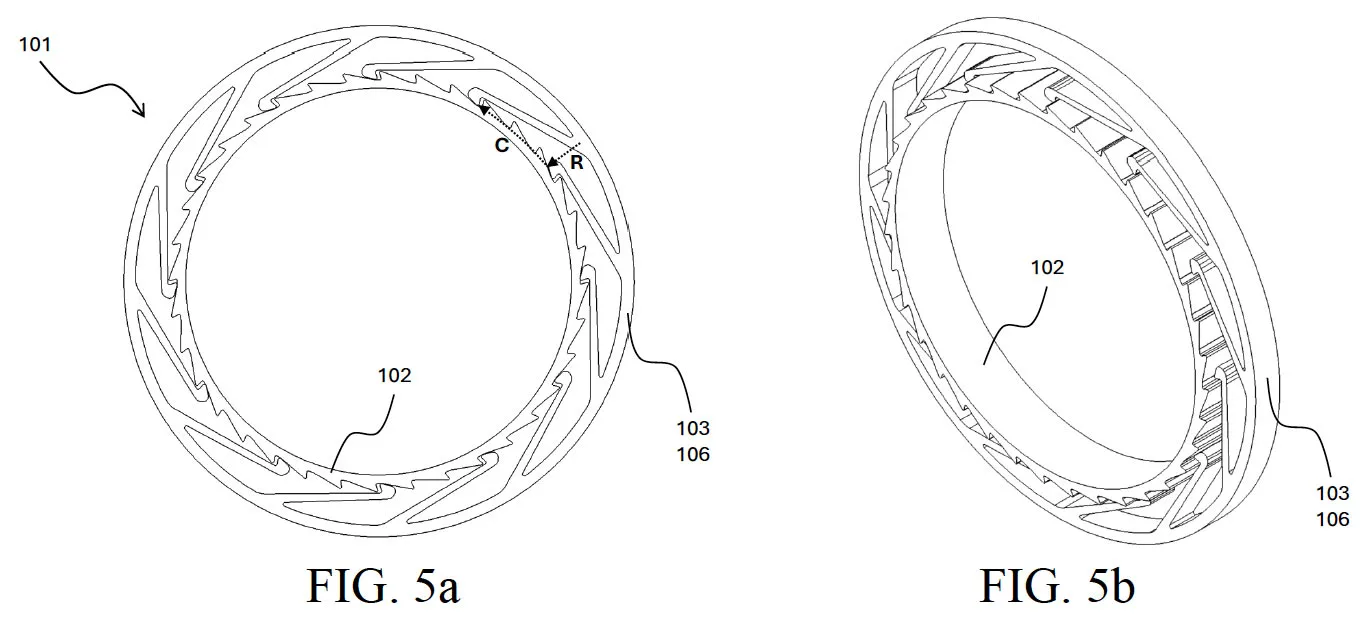

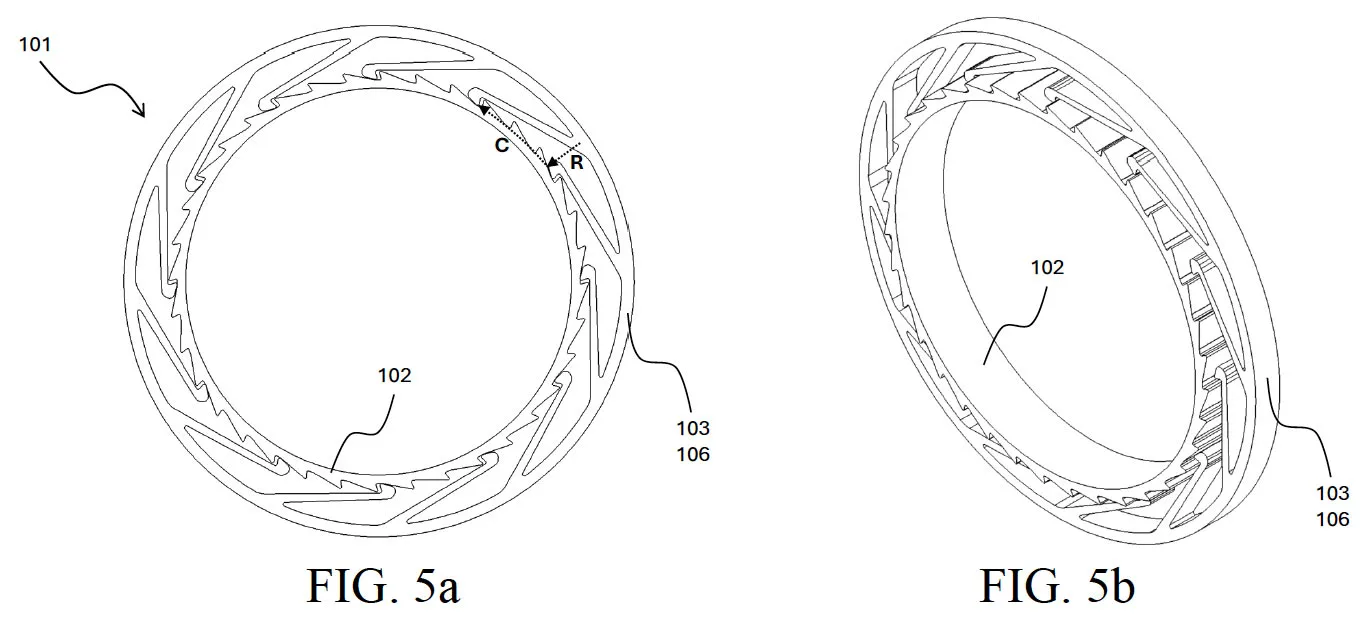

The fundamental premise makes use of built-in pawls (701) made on an interior ring, every basically it’s personal spring with a toothed hook on the finish to have interaction with the tooth (105) on the drive ring (102).

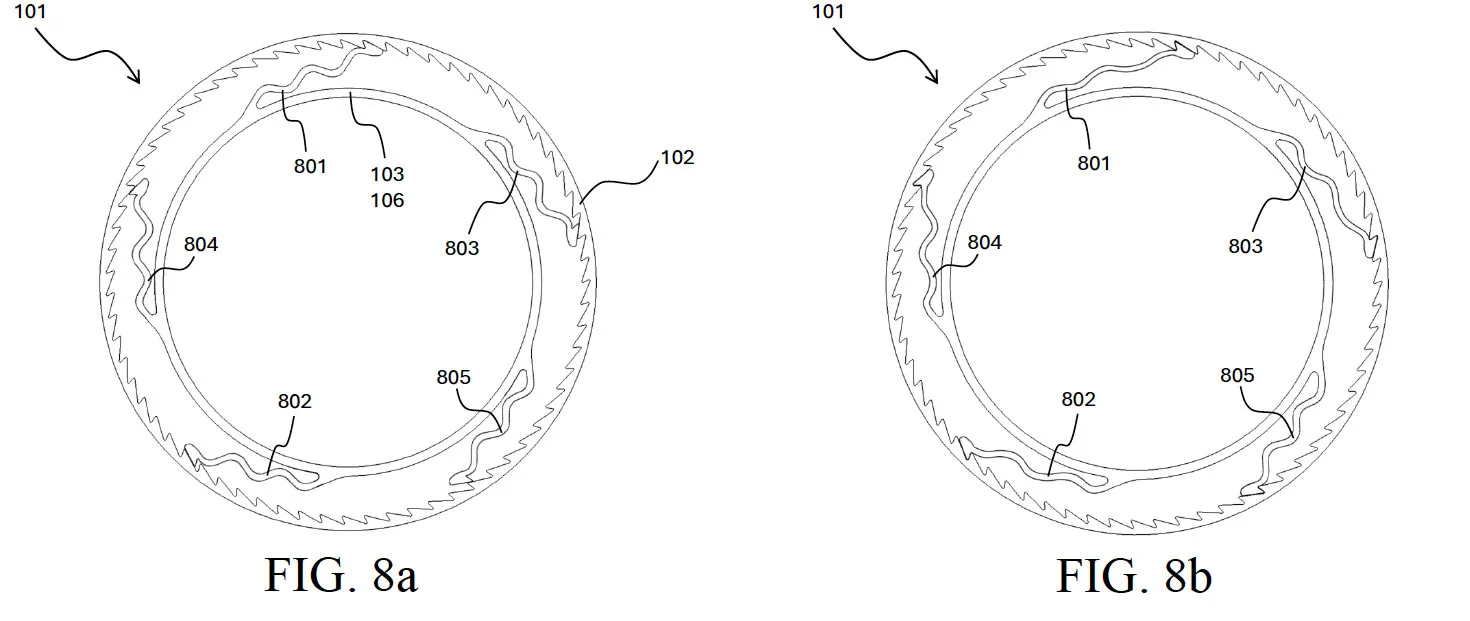

Nevertheless, it may additionally place the pawls on the outer ring and put the drive ring on the interior floor:

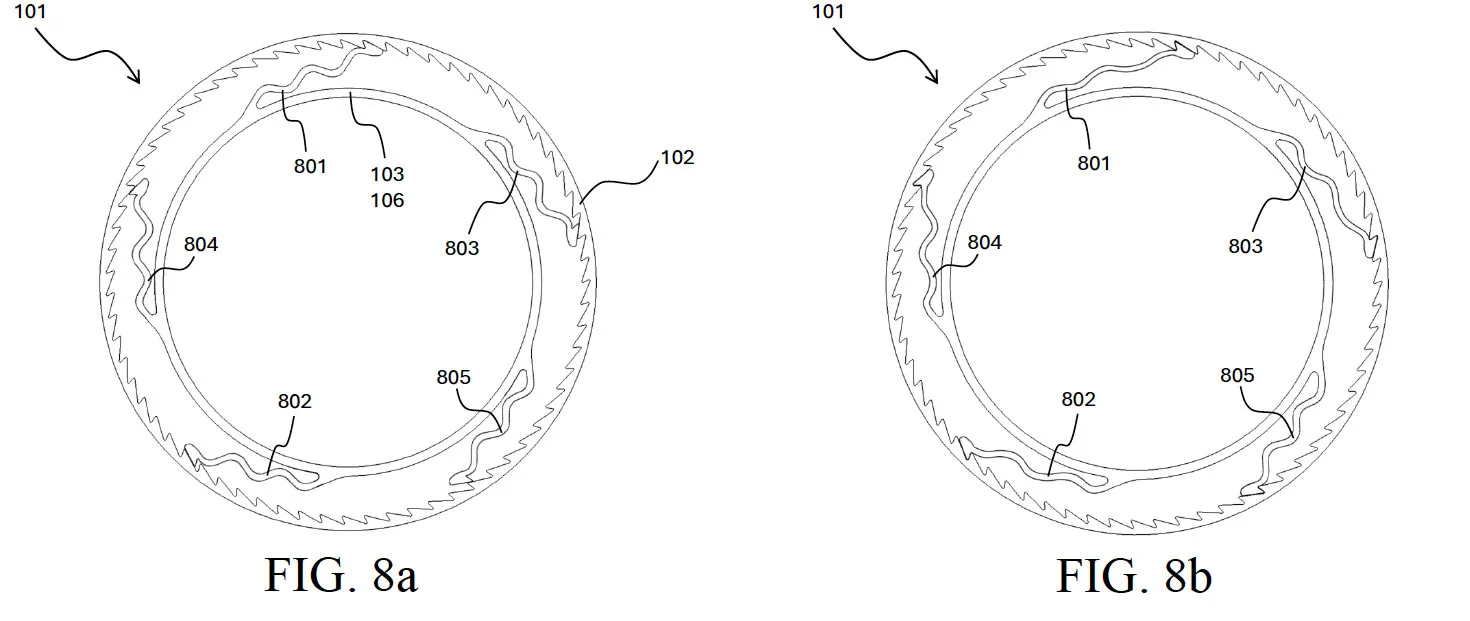

The pawls are staggered to have interaction at completely different factors within the hubs rotation, successfully creating extra factors of engagement with fewer-but-larger tooth. That is what number of present hubs work, often having two or three pawls engaged at any cut-off date. For hubs that don’t want ultra-quick engagement, the pawls may very well be wider (Fig. 5b).

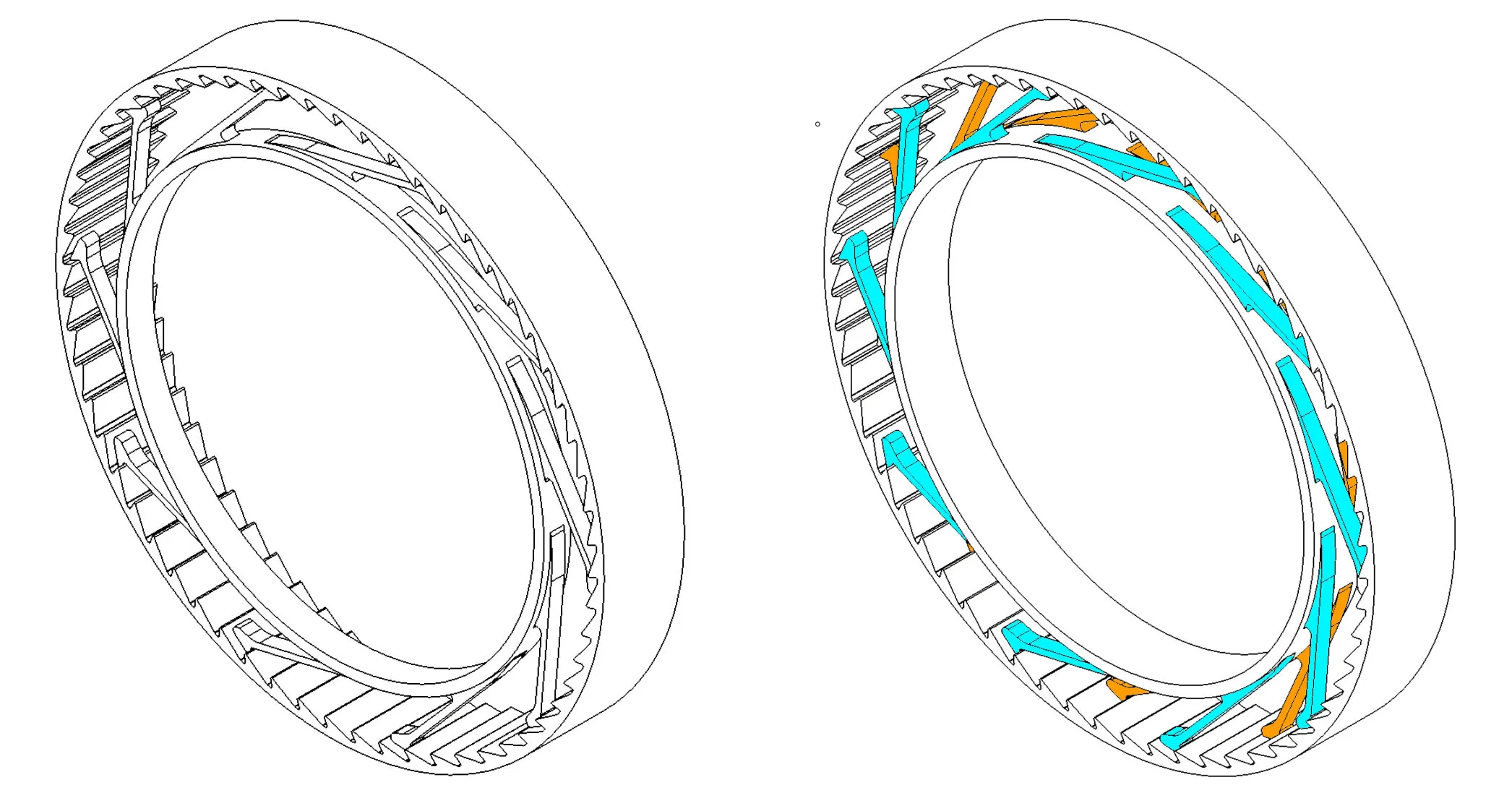

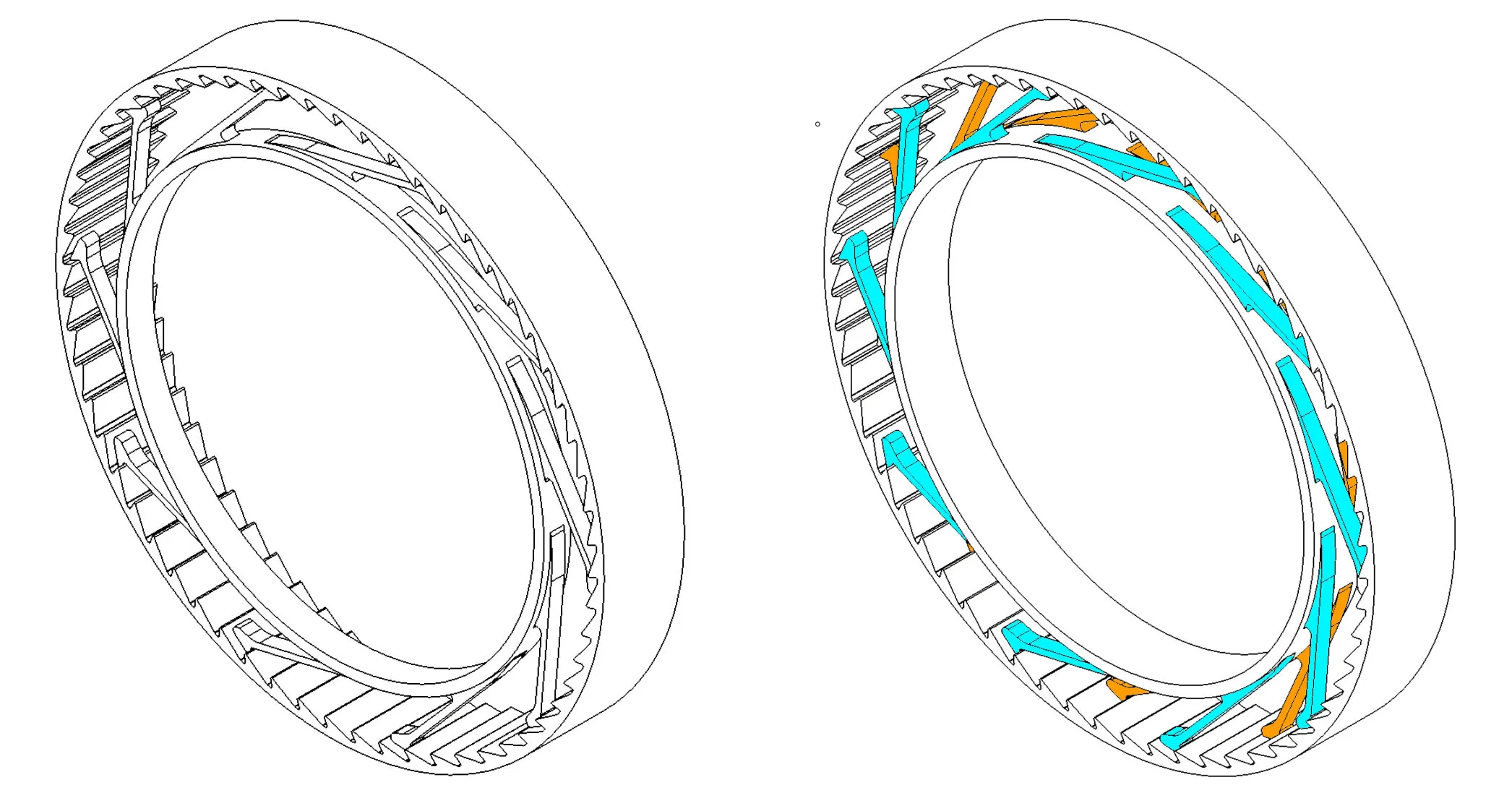

For faster engagement, a second set of pawls may very well be offset from the primary set (blue & orange picture on proper). Or…

…they may even use three units for even sooner engagement (Fig.12). Alternatively, they may use two or three rings in sync to extend power as a result of, admittedly, these pawls must be fairly skinny to suit into a conventional hub design. Assuming that’s what Lauf has in thoughts, let’s keep on that observe for a second.

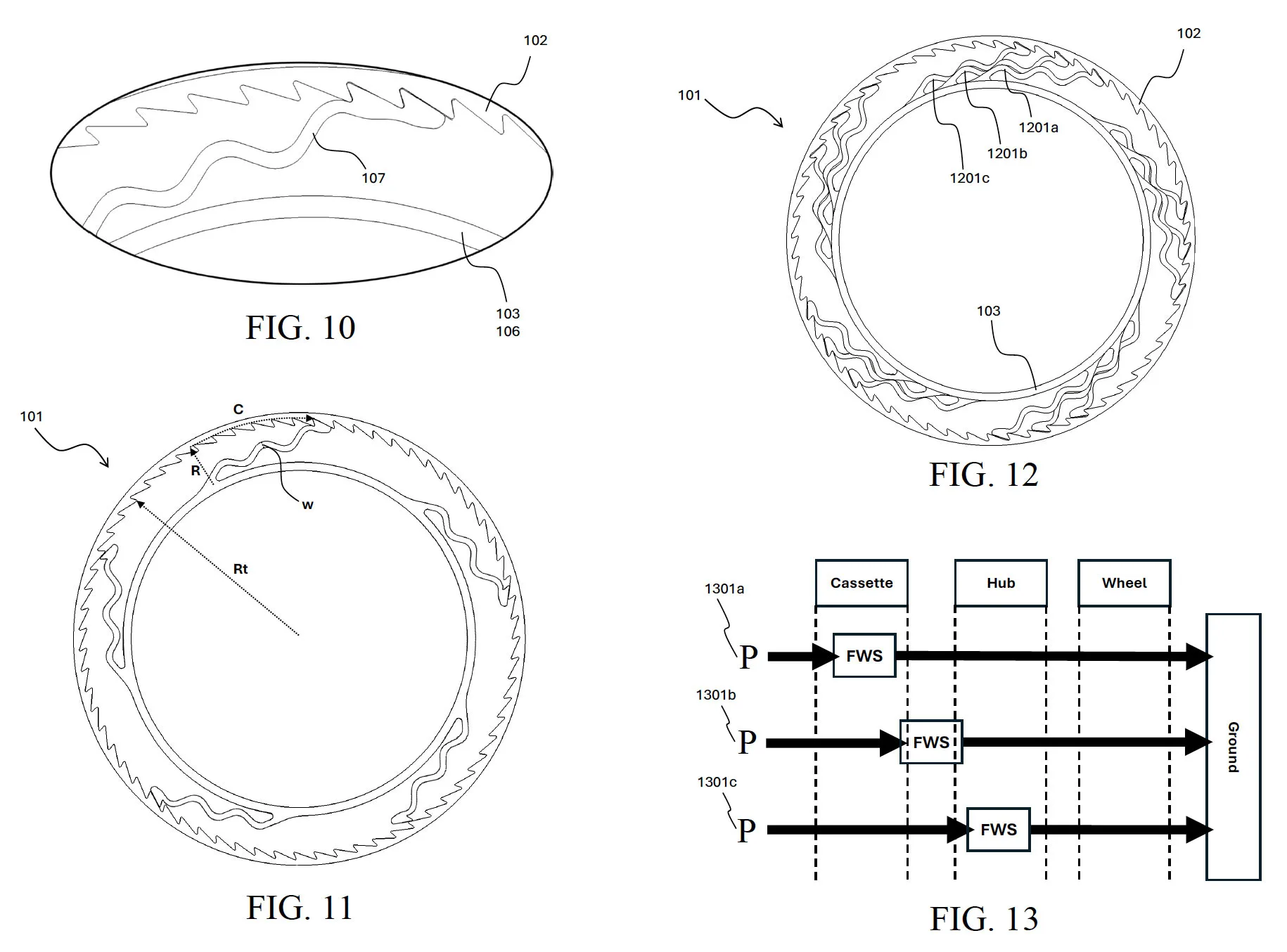

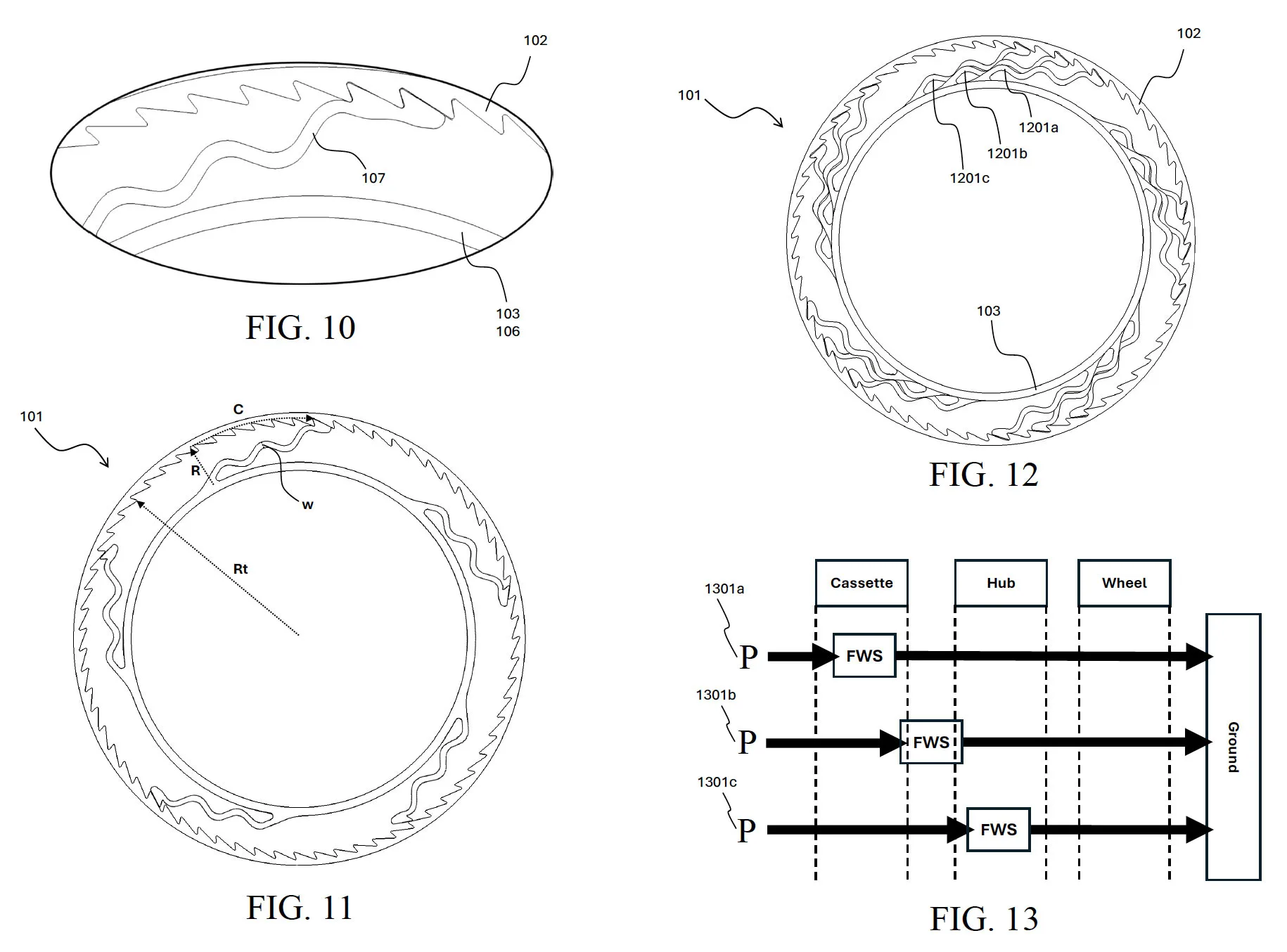

Stretchy, Wavy Pawls

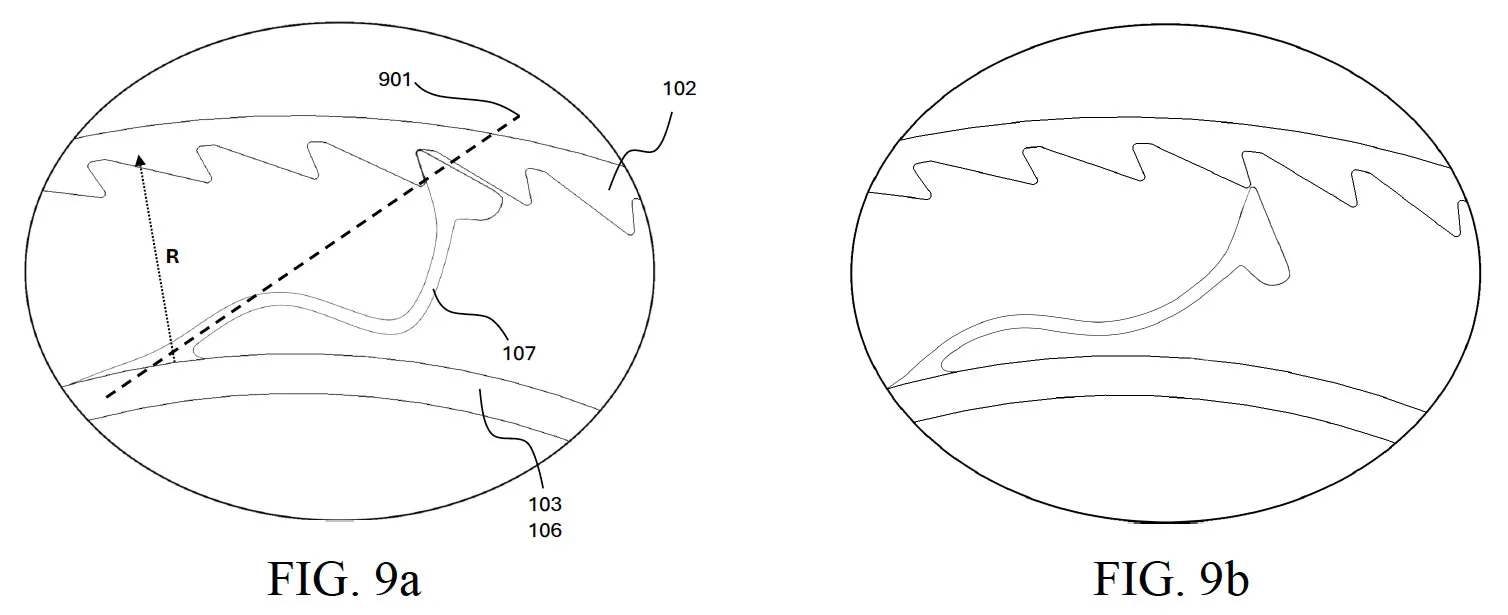

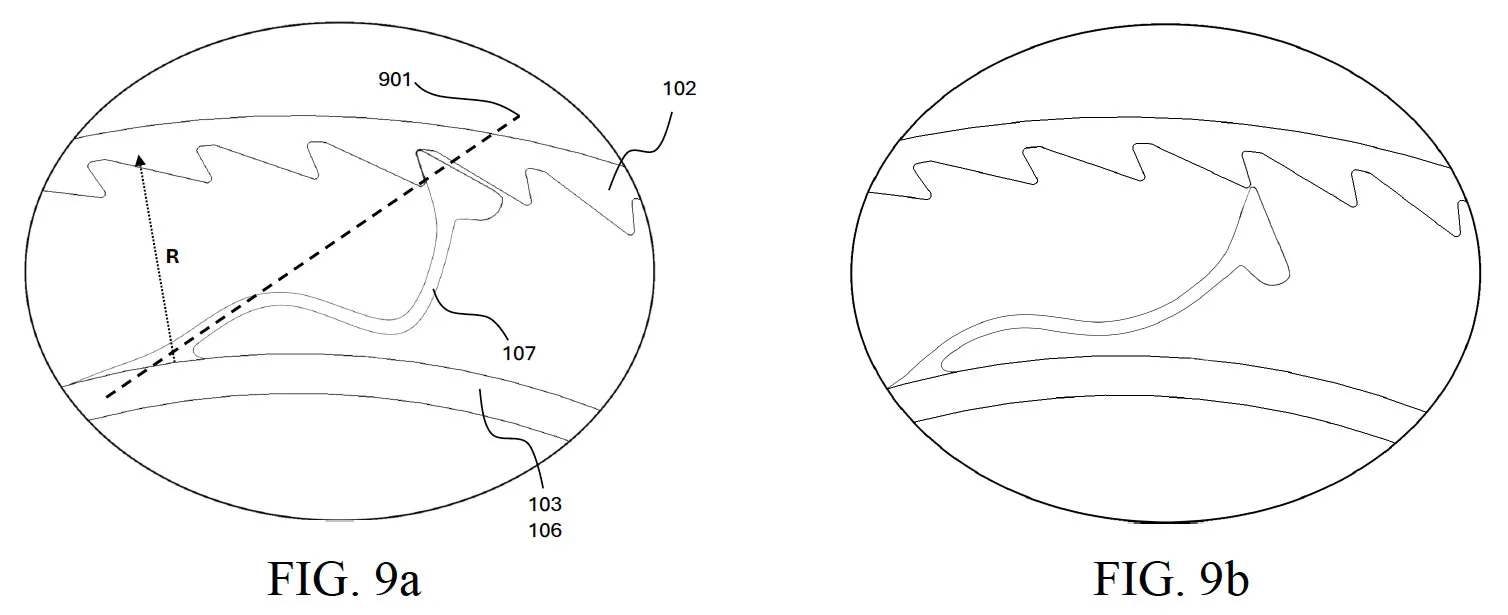

One other tactic for enhancing whole engagement and power is to make use of a wavy form, permitting every pawl to “stretch” barely, simply sufficient such that one set engages first, then they stretch till the second set engages, then these stretch till a 3rd set engages.

The profit to that is that you’ve extra engagement all the way in which across the hub, lowering lateral stresses between the cassette and freehub and hub shell.

And, assuming you apply an excessive amount of torque, that wavy design permits the pawl to breakaway earlier than it snaps. No, that may not be nice for you, however it could theoretically protect your hub. Nevertheless, check out Fig. 13 above for a second, after which scroll down…

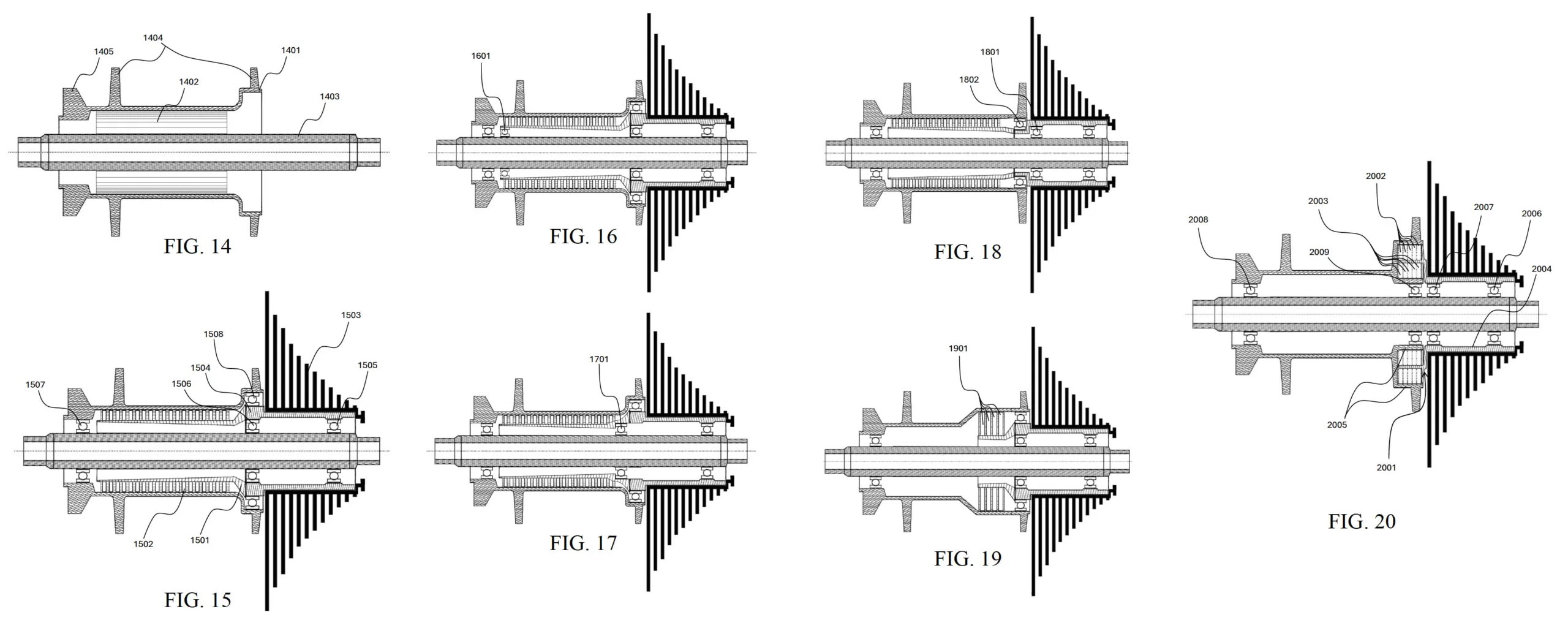

Hundreds of Pawls, Full-Width Freehub Our bodies

What if you happen to crammed your complete hub shell with rows of pawls, offering a large quantity of contact space, every barely staggered but in addition in a position to stretch to permit different rows of pawls to additionally interact?

Not solely would this create insanely quick engagement, however it could present insanely stable engagement, too. Lauf says this additionally offers a a lot better tolerance for pawls and ratchets being out of sync, which they are saying typically are resulting from real-world manufacturing limitations.

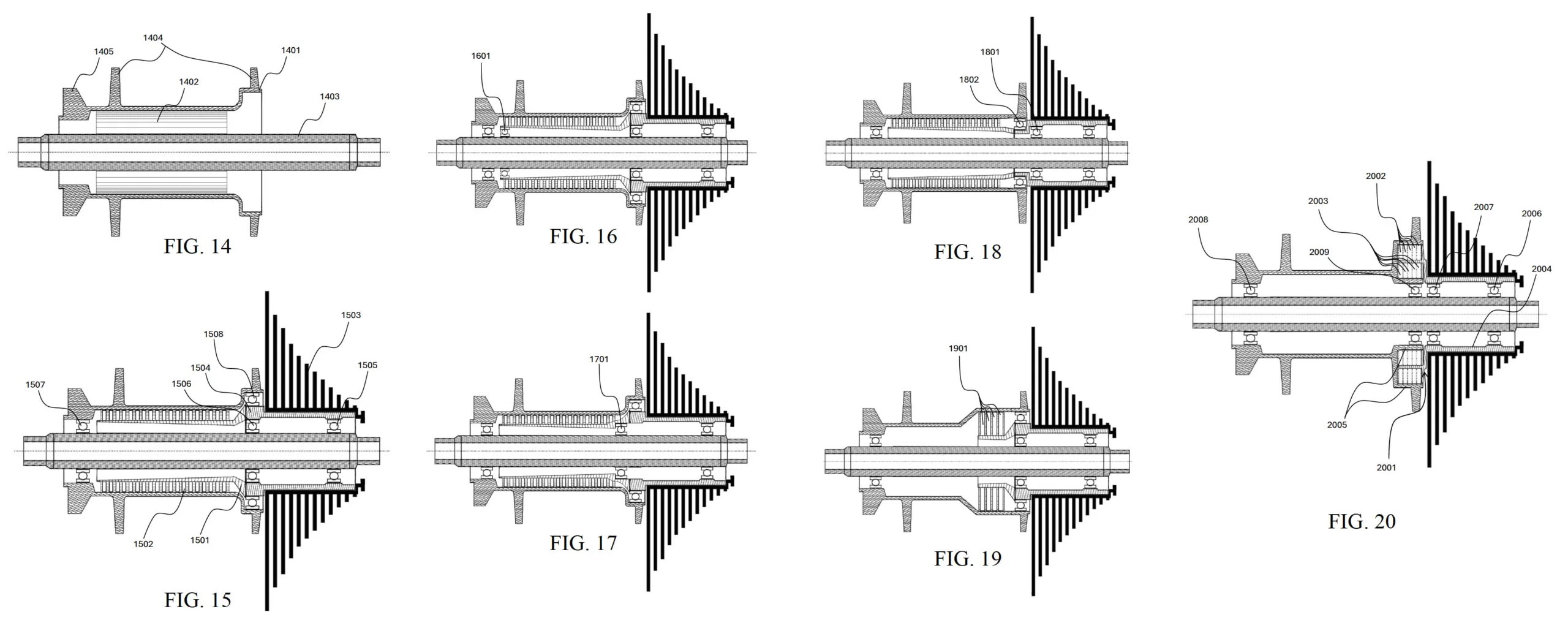

And, as a result of it permits for a full-width freehub physique that’s basically a second axle, it could make your complete meeting much more sturdy, too. Figures 15-20 present a wide range of design choices the place a number of rows of pawls slot in numerous locations and permit for a greater diversity of freehub-to-hub shell interfaces.

Lauf additionally says the “stretch” of every pawl permits your energy to return on progressively (nonetheless in a short time, thoughts you), which eliminates that loud KLUNK, significantly on hubs with decrease engagement speeds. This may increasingly truly cut back put on and tear in your drivetrain, too.

Whereas Lauf is understood for his or her bikes and forks, they’re at all times tinkering. Their possible purpose is to license this design fairly than turn into a hub model, too, however we’ve been shocked by them earlier than, so who is aware of?